The assembly line rose to popularity in the early 1900s as the early versions of mass manufacturing were introduced by the Ford Motor Company. This changed everything about how we manufacture goods. All of a sudden, we could produce much more in a shorter period of time or to use another favorite phrase of mine we increased our leverage.

Fast forward to today and assembly lines have improved significantly by the combination of people and robots working together. They are much more advanced versions of the same concept.

My question for you is, do you know how the industry goes about making improvements to an assembly line?

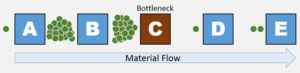

Well it begins by searching for inefficiencies across the entire operation to look for what I refer to as a bottleneck. See the image below for a visual of what I mean.

In this diagram, we have 5 steps to a process (A through E). The green dots represent materials needed by each station along the assembly line (think car parts). When materials start piling up at one station in particular it’s because the station before it AND after it is moving faster than that station. As such, materials pile up and continue piling up slowing the entire process down.

This is where considerable money is lost. Parts that are piling up start breaking, becoming obsolete, wasting space and more importantly cannot be purchased by customers for revenue and profit.

I’m following, but what does this story have to do with where my firm is losing money?

You have a similar situation happening at your firm right now. You might not call it an ‘assembly line’, but you do have an equivalent process that is followed by your team to perform internal and external operations. In fact, you likely have many processes being followed by your team between the areas of client acceptance to service delivery. They key is to find the bottleneck an eliminate it.

Why do we ONLY focus on the step in the process that is the bottleneck, why not upgrade all the steps at once?

We focus on the bottleneck first because that is where we can make the smallest change to have the biggest impact. This maximizes your ROI or return on investment of change management.

Get our awesome product content delivered daily-ish to your inbox

What happens after we eliminate the bottleneck, are we done?

Not quite. You see, the bottleneck never truly goes away, it simply moves to another station. For example, in the graphic above, if we fix the bottleneck at step C then the new bottleneck might be at step B or D. In this case, we repeat the process fixing that step to again maximize our ROI.

How does this translate to our firm losing money?

What the bottleneck really is for your firm is the step in your process that is the most EXPENSIVE. Your team spends WAY too much time on this step and it is slowing your entire process down. As such, if we eliminate it then your team will get the maximum amount of time back which reduces your expenses AND enables your team to focus on more profitable activities further increasing your ROI.

The bottlenecks in your process are both costing you money and preventing your firm from making more.

PS. Go here to learn more about the assembly line or bottlenecks

Talk soon,

Sean